Reviews about the coniferous substrate under the laminate

The quality and durability of the laid laminate will depend on the correct choice of the substrate used. On sale you can find various types of dampers that are designed to level the foundation defects, they differ in their characteristics and cost. There are numerous positive reviews about the coniferous substrate under the laminate, which is characterized by durability and environmental friendliness.

Material Description

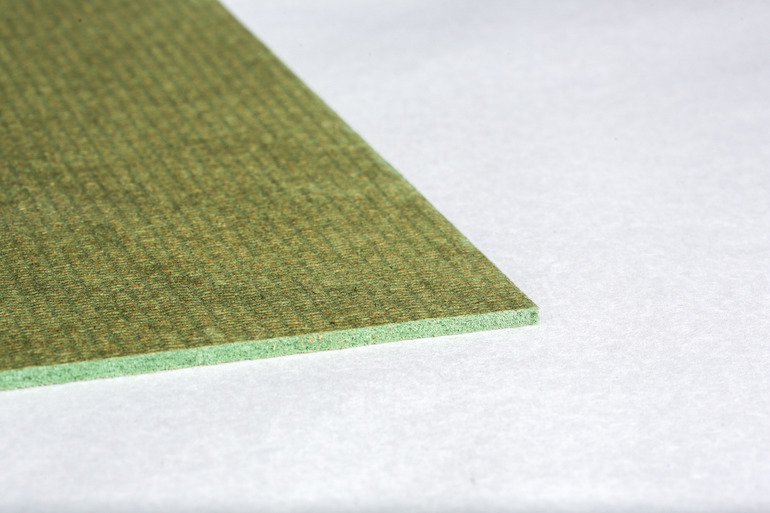

The coniferous underlay under the laminate is a versatile material that simultaneously eliminates floor defects and provides high-quality damping, extending the service life of the laid coating. One of the features of this material is its environmental friendliness and porous structure, which provides excellent sound insulation performance. The coniferous substrate is able to breathe, which eliminates the formation of dampness and mold under the laminate; accordingly, the service life of such a floor covering is extended.

Coniferous backing for laminate appeared in Finland. In this country, environmentally friendly coating is valued, so the Scandinavians decided to abandon the use of synthetic materials, using only natural finishes for home repairs. At first glance, such a substrate may seem overly expensive, however, given its durability, strength, reliability and excellent performance, you should not be surprised at its high cost. On sale you can find various varieties of such dampers, which differ in their size and thickness.

A coniferous substrate is made in the form of sheets and rolls. Both of these materials have their specific advantages and disadvantages. In each case, the choice will depend on the laminate used, the area of the room and the method of installation of the coating. Sheet products are stacked in tight strips, with the fastening of such a substrate to each other using an environmentally friendly adhesive composition. When using a roll damper, laying of the base is carried out from the walls to the center of the room.

Advantages and disadvantages

Coniferous substrate is a universal auxiliary material that can significantly increase the durability of the laminate laid in the room. The advantages of its use include the following:

- the ability to achieve a perfect flat floor surface, even if there are minor defects on the concrete screed;

- excellent sound insulation performance can reduce the noise from walking on the floor, which will be relevant for owners of private houses;

- an excellent rate of water absorption allows you to prevent deformation of the laminate due to moisture;

- coniferous damper creates a layer of thermal insulation, which solves problems with cold in the room;

- the complete environmental friendliness of such a material is explained by the use of exclusively natural components for its manufacture;

- simplified installation technology allows you to perform all the laying work on your own, without resorting to professional specialists.

If we talk about the shortcomings of such a coating, then first of all they note its rather high cost. This somewhat increases the homeowner's expenses for laying the flooring and performing repairs in the house. It is also necessary to take into account the fact that using a coniferous substrate in rooms with high humidity indicators is not recommended.Therefore, when laying the floor in the bathroom, toilet or kitchen, other types of dampers should be used.

The base for laying this material must always be dry, since microorganisms and fungi can develop in wet needles, which is especially often noted when laying this coating on a fresh concrete screed.

Poor quality coniferous boards can have an unpleasant odor, which disappears within 2-3 weeks. Whereas the products of Finnish and German manufacturers solve such problems literally in one or two days.

Right choice

At first glance, choosing a coniferous substrate for a laminate may seem quite simple, however, in reality, it is necessary to take into account the thickness of such a coating and the condition of the concrete screed. When acquiring such a damper, you should keep in mind the existing bumps on the rough floor.

Experts give the following recommendations for selection:

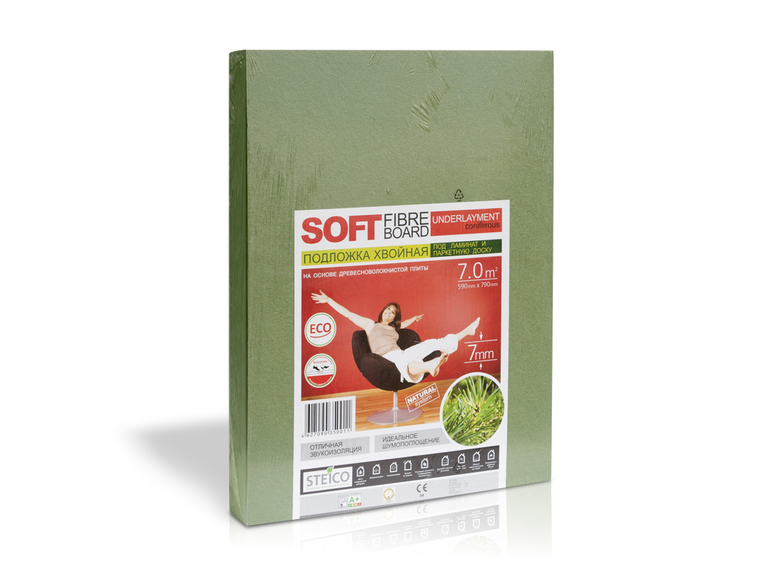

- rolls and plates with a thickness of 7 millimeters will be able to eliminate irregularities and differences of 3 millimeters;

- if the floor has defects of 1-2 mm, then you should choose a substrate with a thickness of 5 mm;

- a substrate and roll materials with a thickness of 4 millimeters will be able to cope with irregularities of 1 millimeter;

- a damper with 3.6 mm thickness is used exclusively for minor defects of the subfloor.

You should not save on the quality of such a substrate, since the durability of the laid floor will depend on the correct choice. Today on sale you can find such materials from domestic, Turkish, Polish, German and Scandinavian manufacturers.

The latter are considered the best, but such a substrate will have an appropriate cost. Whereas domestic manufacturers offer products of not too high quality, which by their characteristics can be stacked only in rooms with a minimum passing load.

Steico underfoor - The products of this manufacturer have proven themselves from the best side, they are distinguished by excellent quality, have excellent sound and heat insulation characteristics. Most often, such a substrate is used for laying floors in a private country house.

Isoplaat It is produced exclusively in the form of plates of various thicknesses, while it is possible to choose the types of substrate that allow laying the laminate on top of a wooden floor. The cost of such products today is 180–200 rubles per square meter of coverage.

Material laying

Laying coniferous substrate is not particularly difficult, cutting of such material is carried out using a conventional sharp knife. Installation of plates is carried out in such a way that the seams do not fall on the connection of boards and lamellas of the laminate.

It is recommended to lay the pillow with a Christmas tree, starting from the far corner end-to-end at an angle of 45 degrees. Such work is carried out exclusively on a quality-dried base in a heated room.

Experts recommend laying a plastic film on a concrete base, sealing all joints with tape, and only cover the substrate on top. Otherwise, the porous material can absorb moisture, which leads to swelling, the laminate swells, requiring repair to be performed anew. Immediately after laying the entire surface of the substrate, you can proceed with the installation of the floor.

Owner reviews

He made repairs in the house and shifted the flooring. I initially thought of using a synthetic backing, but coniferous slabs were recommended in the store. Yes, such material is quite expensive, but it is completely environmentally friendly. Now the floor does not blow cold, the laminate has been lying for a couple of years, and there are no problems with it. At first there was a slight smell, but it passed literally in a couple of days. All repairs were carried out independently, saving on the appeal to professional builders. I recommend to everyone such substrates from pressed needles.

I wanted to shift the floor in the hallway, hall and kitchen.I went to the Leroy Merlin store, at first they offered me linoleum and cork flooring, and for such a coating we recommended wood fiber. I began to read reviews about the spruce substrate under the laminate, I learned all the pros and cons of such products. It turned out that they can only be placed in rooms with normal humidity indicators. I acquired such material, but I used this damper exclusively in the living room and hallway.

He planned to carry out repairs at home, it was necessary not only to choose a laminate or parquet, but also a coniferous substrate for such a coating. He chose the material Ecosilk. Such a coating of isoplate turned out to be durable, durable, the laid floor does not creak, they solved the problems with cold from the floor, and I did all the work myself, which significantly reduced the cost of repairing the house. I recommend everyone to use such a coating, it is completely environmentally friendly, differs in the quality of manufacture, and working with it is a pleasure.

Finally he decided to make repairs in the living room, removed the old floor, and the base was not too smooth. He poured a leveling screed, laid a substrate of needles on top, and mounted a laminate on top of it. I am completely satisfied with the choice made, the floor made by me is of high quality, it does not play and does not bend, there are no creaks. It is completely uncomplicated to work with such a damper; it can be cut with a clerical knife; in addition, I also used liquid nails to fix the substrate to the floor.

I read numerous reviews on the Internet about the 3 mm coniferous substrate and decided to use it for laying in the combined living room and kitchen. I will say right away that I decided to save on the purchase of such a damper, went to the nearest construction market and purchased the cheapest material. He made repairs and the floor began to creak. I decided to carry out all the work again, after which I already bought a high-quality substrate, now all the problems have been solved. I can advise all homeowners not to save on the quality of materials, and then you can make a good and proper repair.

- How to choose a vacuum cleaner taking into account the characteristics of the house and coatings?

- What to look for when choosing a water delivery

- How to quickly create comfort at home - tips for housewives

- How to choose the perfect TV - useful tips

- What to look for when choosing blinds

- What should be running shoes?

- What useful things can you buy in a hardware store

- Iphone 11 pro max review

- Than iPhone is better than Android smartphones