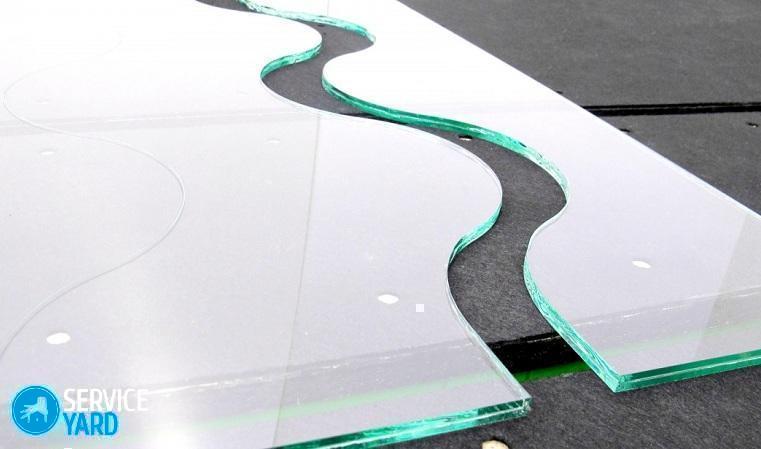

Glass cutting at home

Glass cutting is almost the same as jewelry craftsmanship. For real specialists, they can make real masterpieces from a piece of this material. But in order to achieve this, a lot of experience will be required. And in between, some do not even manage to cut the glass into two pieces, as they are not familiar with the basics of cutting. Consider what glass cutting is at home and how to properly perform it.

to contents ↑Choose a glass cutter

In order to facilitate the cutting process as much as possible, they use special tools - glass cutters. They are represented by three main types:

- Glass cutter, a cutting tool which is made of natural diamond. Such a device has the greatest popularity. Thanks to its tip, glass with a thickness of less than 10 mm can be cut. The cut in this case is perfectly flat, without defects.

- Roller cutting tool. In this case, the working tool looks like a roller. The diamond in this embodiment is replaced by a special alloy of hard metals, most often tungsten and cobalt.

- Oil glass cutters, which differ from the roller versions by the supply of special oil lubrication to the cutting tool. Due to this, the service life of the roller mechanism is extended.

Training

There are some rules that must be observed when preparing glass for cutting. Do-it-yourself glass cutting will be successful if the material is previously:

- Wash and dry, as the roller quickly deteriorates due to dust and water;

- Degrease;

- Warm up and wipe if it was outdoors in the cold season;

- Wipe with a soda solution.

Important! Before cutting, make sure that there are no scratches or microcracks on the material.

And a few more tips:

- In order for the process to be convenient and non-traumatic, preparation of an even clean horizontal surface and gloves is required.

- To mark the glass we use a ruler and marker.

Important! When marking, be sure to consider the distance between the cutting edge and the ruler. It is equal to the thickness of the roller holder.

Before you cut glass with a glass cutter at home, it is better to practice a little on the fragments. This is done in order to test the video:

- If the first strip is transparent and colorless, the video is of high quality.

- If white and rough - it needs to be thrown away, it has become dull.

How to use a glass cutter?

For cutting to be of high quality, compliance with the technology and sequence of actions is required:

- On the sheet of glass points are marked at which the beginning and end of the cut will be.

- The glass cutter is placed at the starting point, a ruler is attached to it.

- In one smooth movement with effort, a cut is carried out. In no case should you repeat it.

- The cut piece is chipped. To do this, the cut line is aligned with the edge of the table, you need to lightly tap the cut with a glass cutter, and then break off the unwanted glass with one sharp movement.

Important! If the chip is uneven, pliers are used to remove the excess. So that the material does not crack, the edge is wetted with kerosene or turpentine.

- The cutting line is processed using sandpaper, velvet file or grindstone.

Other cutting methods

But how to cut thick glass at home without a special tool? It turns out that you can use non-standard options for this:

- a soldering iron;

- grinder;

- nichrome thread;

- ordinary scissors.

Consider them more carefully:

- Soldering iron. With it, cuts are made on the cut line, at the beginning and end. Then a heated soldering iron is carried out along the entire line. The temperature difference leads to the appearance of a crack on the surface of the material, after which it must be carefully broken off.

- Bulgarian. How to cut thick glass at home? It is enough to use a grinder with a thin diamond disk. The disc runs along the entire cutting line, after which a thin groove remains. Be sure to use eye protection and respiratory protection, as problems can occur due to the finest glass dust.

Important! When using a grinder, it is necessary to ensure that the material does not overheat. Be sure to use coolant.

- Heating and cooling. A thread pre-soaked with a combustible substance is laid on the cut line. Then the thread needs to be set on fire, and after attenuation, cool the material with water. A sharp temperature difference will lead to a crack.

- Scissors. For cutting not thick glass up to 3 mm thick, ordinary tailor scissors are used. To perform this operation, scissors and glass are immersed in a container filled with hot water.

Stock footage

If you want, you can do everything! The most important thing is to cut small pieces before cutting large glass. It is equally important to take care of the protection of the eyes, hands and respiratory organs. And having mastered the technology and skills, any glass crafts will become an interesting and feasible task for you.